Customer Services

Copyright © 2025 Desertcart Holdings Limited

🖤 Print Tough, Print Smart — The PETG Power Move

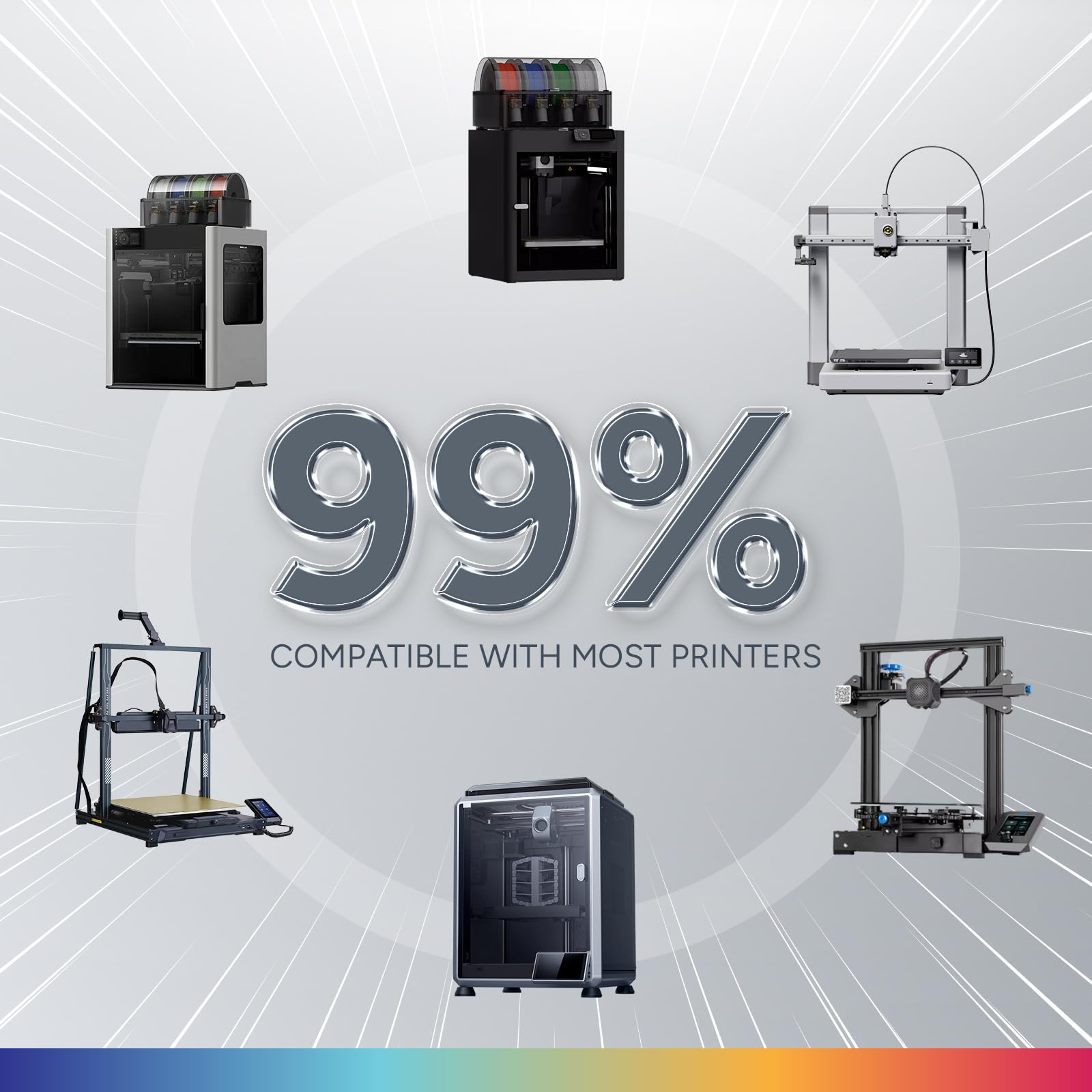

OVERTURE PETG 3D Printer Filament delivers industrial-grade strength and precision with ±0.02mm accuracy on a neat 1kg spool. Engineered for superior layer adhesion, heat and impact resistance, it’s perfect for functional, durable prints that outperform PLA and print easier than ABS. Compatible with most FDM printers, this filament ensures smooth, tangle-free printing and vibrant, fade-resistant colors backed by a 1-year warranty.

| ASIN | B07PGYHYV8 |

| Best Sellers Rank | #40 in Industrial & Scientific ( See Top 100 in Industrial & Scientific ) #4 in 3D Printing Filament |

| Brand Name | OVERTURE |

| Color | 1 Kg Black |

| Customer Reviews | 4.3 out of 5 stars 17,971 Reviews |

| Item Diameter | 1.75 Millimeters |

| Item Weight | 1 Kilograms |

| Manufacturer | OVERTURE |

| Material Type | Polyethylene Terephthalate Glycol |

| UPC | 850006233403 |

| Unit Count | 35.274 Ounce |

| Warranty Description | 1-year Warranty |

J**T

Great PETG for my project. 250C was sweet spot, and prints perfect on Sovol SV07+ PEI bed.

Grass Green is pretty close to Ryobi's green. I printed PETG and found 250C, the max, was best. I also noticed it printed more shiny at higher temps. Duller at lower. 70C bed was fine and 80C no different on Sovol SV07 PEI bed. Fast led to problems. Sweet spot was around 38mm/sec for walls. If I dialed it up to 50mm/sec then stringing started. On a roll sitting for about 3-4 weeks it did pick up moisture which can cause your nozzle to accumulate some excess. Keep an eye out for it. If you come back to a final print with little extra blobs, it's probably knocked off the nozzle as it moved around. I used Cura default for wall thickness but I did drop my layers to 1.6mm for better arches. I didn't use bed adhesion (brim, raft, etc), bridges or supports but I also kept all my angles gradual. Look at the pic and you'll see they are basically circles. I used 20% infill as well as 30%. No real difference. When setting the power drills on the bracket arms, they only deflect maybe 1-2mm. Barely noticeable. Yes, by hand you can make it deflect 5-6mm but this is just to organize my tools, not create a climbing wall that will support lots of weight. I printed all of what you see with 1 spool. I have a 2nd loaded to do a ton of more tool wall brackets, but wanted to get this review up. If your print has started, and you have moisture issues, try bumping the temp up and keep an eye on it. You may get through it bumping 5 degrees at a time to watch for change. In my case, it was in the infill area, and so it's "entombed" inside. When I ramped up to 60mm/sec and got to higher layers, like around 300 of 500 (again, 1.6mm height layers) it did start to have issues rising a bit, and catching upon hot end return. I reduced the speed back to 32, and dropped the fan from 20% to 10% and the clipping stopped for a perfect finish. I do also use glue pen for adhesion to the bed, but even on a clean bed (no glue pen) I still had great adhesion. Finish is great. No stringing if I keep speeds down. Strong as you'd expect from PETG. I am super happy. I did read reviews that were negative but didn't have problems. The storage bag is resealable which is really nice. Spool did not detach on either spools. My filament was unopened on both rolls, ordered about 4 weeks apart. I will definitely order this product again as I get more of my power tools wall mounted, and when I get a chance I will upload the STL files to Thingiverse. I created these prints on TinkerCad. website, exported STL into Cura and then sliced GCode sent to Sovol SV07Plus.

J**R

Excellent quality. Rosey color.

First thing I did was put it in a dryer for a few hours. I have no experience with this material straight out of the box. I've used a few rolls of Overture transparent red. Print quality is excellent. Bed adhesion is as I would expect for PETG at proper settings. Filament is in neat rows as I've come to expect from Overture. This is good material. My only complaint is the color; it's a little "rosey" for my use. On a RGB color wheel, I'd say this Overture transparent red PETG is a #350 hue. I've previously used ERYONE transparent red which is closer to #5-10 on that same color wheel, "candy red". See photo, Overture on the right. ERYONE is also a little brighter so it catches the light and "glows" a little better, so I'll be going back to that. My application needs a certain shade. Otherwise, the Overture transparent red PETG is perfect. Transparent PETG Tip: Use warmer, slower settings with as little cooling as possible for the best rich color. Turn off fans altogether if the design allows. Printing fast with fans on will result in a matte finish that won't have the same color depth.

W**.

A high quality PETG at a great price

Filament came tightly vacuum sealed in a UV resistant silver plastic. It printed beautifully right out of the box without needing a drying cycle. The diameter is consistent, with no under- or over-extrusion. I did have to adjust the Flow Rate down slightly on my X1 Carbon - I think it veeeery slightly over-extrudes on the first layer, and dropping the Flow Rate to 0.93 seems to help. I have not experienced any clogging issues with the filament. I have printed well beyond the 50mm/s speed recommended in the pamphlet with no stringing issues, even with a nozzle temp of 255C. The black color I purchased is well pigmented and opaque. Overall, I am happy with the purchase. I also bought a spool of PETG white that I haven't used yet, but I expect similar results.

K**C

Not as easy as PLA but really nice once dialed in

The only reason for 4 stars instead of 5 is because of their claim "prints easy like PLA." It took me a few failed prints using settings they list on the packaging before i finally got it dialed in. By contrast, PLA is much less finicky and has a lot more wiggle room. The initial problems i had on the failed prints were the printout being too brittle, bad bed adhesion, and really bad stringing. Once i managed to dial it in though, it was as good as i can expect from the base model Ender 3. Actually i think the print quality was better than their own PLA. But again, i would not agree with it being "easy." The only upgrade i have is the glass bed. The "clear" miniature in the pictures was printed with a 0.4 mm nozzle and 0.16 layer height (more slicer settings listed below). For comparison the painted model is PLA 0.12 layer height and a glued-on acrylic base. The paint fills in most of the layer lines though anyway. One of the pictures makes it look like there might be bubbles but i assure you that's just model detail and light refraction. My intention was to print out copies of my miniatures with the clear PETG to indicate when they're invisible. I knew i wouldn't achieve anything close to glass but i thought i'd get more translucency than what i got. I'm not a 3D printing expert so maybe you can get better results than me. There is some very minor stringing around the hands but it did fantastically with everything else despite being so small. There are a couple support artifacts leftover on the circle base but that's just my fault. Another thing to note is that the hardness of PETG is quite noticeable compared to PLA when doing cleanup on the printed model. Just FYI the painted miniature was printed in OVERTURE white PLA. I've never had a problem with OVERTURE filaments and i don't see any reason to buy from another brand. I don't even have a filament dryer but the filament has always been reliable even when sitting for a couple years. I'll update this in case my experience changes with the PETG. These are the main points in the slicer settings i used for the miniature. Layer height: 0.16 mm, wall line count: 1, infill density: 100%, infill pattern: Lines, connect infill lines: Enabled, infill line directions: [45], infill overlap percentage: 15%, printing temperature: 245 C, build plate temperature: 80 C, (all) print speed: 20 mm/s, travel speed: 150 mm/s, enable retraction: Enabled, retraction distance: 3 mm, retraction speed: 20 mm/s, enable print cooling: Enabled, fan speed: 30%, initial fan speed: 0%, generate support: Enabled, support structure: Tree, build plate adhesion type: None. I use generic glue stick on the glass bed and do the slicing in Cura 5.9.

H**S

Easy to print and strong

Good PETG for the price. It is not too picky on temperature, it prints fine anywhere from 245-255 on my Ender 3 V2. It doesn't bridge very well but that is to be expected for PETG, if you want to bridge I recommend printing at 245 and turning on bridging settings in Cura which makes bridges possible although pretty ugly. Supports work better than bridging, but can be hard to remove because PETG sticks to itself so well. Here are my settings for Ender 3 v2: micro swiss all-metal hotend / original extruder / original bowden tube bltouch leveling probe + yellow springs nozzle 0.4mm 250c bed plain glass + gluestick, 85c first layer speed 10 speed after first layer 30 first layer height: 0.28 layer height after first layer: 0.2 fan: none unless you are trying to bridge, if so use bridge detection to turn fan 100% only for the bridge retraction 3mm @ 30 I find that the biggest struggle with PETG is just getting the first layer to stick and look good. Once you get past the first layer it is usually smooth sailing. If you have problems with the first layer, first of all dry your filament even if it is brand new. It is an easy way to eliminate frustrations. Also go ahead and calibrate your extruder steps and measure your filament diameter and put that into your slicer, again these are easy steps that ensure you will not be fighting under/over extrusion while you are trying to get everything else figured out. Next use glue stick on plain glass and let the glue stick dry. You want the glass to look dull, not shiny, but it also shouldn't feel sticky to the touch. This combo works great for me, it adheres well but not TOO well and the prints pop themselves off when they cool. Lots of people like hairspray too but gluestick works fine for me and is less messy. Finally the #1 most important thing is to adjust your z offset and first layer height. You cannot mush the filament onto the bed like PLA, it needs to fall out of the nozzle and gently lay down onto the bed. Before doing anything with your z-offset I recommend turning your first layer height up to .28 or .3. The reason is that this sets your nozzle higher AND automatically adjusts the flow rate to match. If you just start bumping your z-offset higher and higher, you will be under-extruding by a lot which can cause its own problems. Once you set your first-layer height to .28, then start printing a test print and live-adjust your Z until the lines lay down and stick to the bed, and are neither gooping up onto the nozzle, nor being hit by the nozzle and pulled off the bed. This is tricky because the sweet spot here is TINY. Like within one or 2 micro-adjustments on the z, either side of that you will have issues. But once you hit the sweet spot on the Z you are golden. Then print some bed leveling test prints and adjust your first layer extrusion multiplier or line width if needed so your lines are touching. I recommend always using the bed level print that is CIRCLES when starting off, not squares. The sharp corners on the squares are super unforgiving and will pop off instantly if your settings aren't right. It is easier to use a bed leveling print with circles to dial your settings in without frustrating yourself and needing to restart the print a hundred times. When printing things over 2" tall I recommend using a wide brim because originally I was using skirt and I have had taller prints pop off the bed right as they are nearly finished, I think the reason is due to the lower part of the print cooling off. A brim is cheap insurance against your whole print being ruined at the last moment, and is easy to remove and leaves little trace that it was ever there.

E**R

More versatile but slightly more temperamental than PLA+

***Update*** TLDR: Downgrading to 2 stars due to inability to finish larger and/or more complicated builds with this filament. This filament is proving to be very temperamental in my Ender 3 v2. The problem seems to be with the Bowden tube (or there is already a spiral tension in the filament as it is wound on the spool at the factory). As a piece is printed, the filament spirals as it flexed through the Bowden tube to the hot end. As this filament has a fair amount of elasticity (much more than PLA), this torsion doesn't extrude out the hot end but instead starts to translate through the filament back to the feeder. First will come the clicking as the filament starts to bind up in the Bowden tube and at the feeder; this is the combination of the feeding gear/bearing trying to grip onto filament that is under increasing spiral tension (think of twisting fibers into a thicker and tougher strand of rope) and slowly begins to strip the "bite marks" off the filament, especially during retractions. Eventually, the filament will twist and be stripped to the point of fracture. The filament going into the Bowden tube stops advancing to the hot end, and a strand of filament comes out of the feeder anywhere it can escape This happens even after upgrading to Capicorn Bowden tubes, playing around with the "grip" tension of the feeder, cleaning the hot end barrel, setting the screws holding the feeding gear/bearing to the right torque, etc. (One can pull out the filament from the Bowden tube and see a spiral staircase imprinted by the extruder all the way down to the hot end.) The solution is to remove all of the filament that has passed the into the Bowden tube and re-load virgin filament. Then it will print fine until enough torsion builds back up again. However, if a piece requires quite a bit of retractions, then this will happen much sooner - somewhere between 3-6 meters of filament. This isn't because of less torsion, but because the feeder is pushing back and forth on a piece of filament that is becoming less compliant and more difficult to handle, which quickly wears off the "bite marks" and erodes the filament into a thinner strand. If the feeder bites into a virgin piece of filament, then it can maintain bite for a bit longer, but spiraling will still eventually happen. I'm taking away stars as it's not usable for large builds or builds requiring a lot of retractions. Not dropping past 3 star as the prints that can be completed are translucent with a good mix of elasticity and strength/durability. However, this makes working with this filament much, MUCH more frustrating than more forgiving alternatives like PLA. Beginners and those with Bowden tube printers should probably use this filament with caution due to the frustration that awaits. Those looking for unique PETG properties might consider giving this a try. I don't know how this filament behaves under a direct extruder, but I suspect results may be better as it seems that the back and forth flexing of the Bowden tube is what is applying a "crankshaft" effect on the filament that is torsioning the filament. ***Initial Review*** Previously, I used only Overture's PLA+/PLA Pro filament (which is a great PLA filament, BTW), but I wanted a filament with greater strength and unique features (i.e. translucency). Still being relatively new to 3D printing, only printing/experimenting during my scarce spare time, and not having a specific application demanding rigorous specifications for printed parts, I opted for PETG over more specialized filaments that reputedly require more more experience and time to get right. First, Overture's quality is great. Their clear PETG filament is white without any perceivable tint. It feeds great; hasn't clogged or tangled. It's labelled as clear, transparent, or translucent. It's best described as translucent (although I have seen some reviewers here polish their prints until clear/transparent. So it is possible to get crystalline prints - but I've not tried this as I don't have the time/patience). When printed at the higher end of the recommend nozzle temps (my settings, 245C), prints appear more glossy. However, I have to use 90+C bed temp to prevent warping, and I also slow down the print speed and increase retraction to reduce stringing. It still strings quite a bit. I haven't found the right settings yet, so I use these settings for parts where the stringing primarily affects/hidden amongst infill. When printed at the lower end of the recommended nozzle temps (my settings, 225C - which is lower than Overture's recommended range - bed temp 80C), prints appear more matte. However, handling feels more like PLA with improved details and much, much reduced stringing. I've tried to go down to 220C, but I starting having adhesion issues. I have prints comparing both settings (print and fan speed set to same). The left clip was printed at the higher temp and the right clip printed at lower temp. For the gears, the right gear was printed at the higher temp, and the left gear at the lower temp. Glossy doesn't necessarily mean more transparent, although one can see very slightly "deeper" into the glossy print. Both exhibit more of a frosted glass appearance; glossy just means more reflective and less surface friction (i.e. the glossy gear spins slightly more quietly than the matte one, which is already much more quiet than PLA due to increased plasticity/elasticity of PETG). I'm still working on getting the right settings. But from what I see so far, I would recommend Overture to anyone working with PETG.

S**I

Reliable PETG with strong parts and a clean white finish

I’ve gone through many spools of Overture PETG (White) and it’s been a solid, predictable filament for functional prints. The spools fed smoothly and the filament stayed consistent throughout longer runs, no weird extrusion swings or sudden quality drops. It’s a 1.75mm PETG with a tight tolerance (listed as ±0.02mm) on a 1kg spool, which is exactly what I wanted for repeatable results. Print-wise, PETG needs a bit more heat than PLA, but once dialed in it’s very forgiving. I landed close to the manufacturer’s suggested range (roughly 230–250°C nozzle, 80–90°C bed, moderate speeds, fan on), and got strong parts with great layer bonding and a nice subtle sheen. Only note: like most PETG, keeping it dry matters, if it’s been sitting out, a quick dry helps keep prints clean.

S**.

Print Slow & Hot to Get Maximum Clarity Possible

Overture transparent PETG is widely reputed as among the very best for achieving “glass like” clarity with careful tuning of your slicer settings. Thus, I decided to give it a try on my Bambu Lab X1E. I set a custom filament profile via Bambu Handy, titled “OVERTURE PETG Transparent @ Bambu Lab X1E 0.4 Nozzle”. If I understand correctly, this profile should update to the Bambu cloud so that other users can pick and use the profile for their prints. I started with the “Generic PETG” profile and amended the following: Flow ratio = 1.01 Max nozzle temp = 270 deg C Nozzle temp = 270 deg C (for initial layer & other layers) Minimum fan speed = 0 Maximum fan speed = 0 The slicer setting are absolutely essential: Wall loops = 1 Top shell loops = 0 Bottom shell loops = 0 Sparse infill density = 100% Sparse infill pattern = Aligned Rectilinear Infill direction = 0 deg (or 90 deg) Change all print speeds to 1/10th the defaults = 20 mm/s for most settings Layer heights (all) = 0.1 mm Line widths (all) = 0.5 mm Seam = I used “Back” (avoid using ‘Random’) Some design tips: 270 deg C nozzle temp is needed to create the infill to be as solid (unified) as possible, but be careful about avoiding overhangs and bridges as with the cooling turned off completely the filament will droop / sag extensively at such high nozzle temps. Even 45 deg overhangs will not print well. Thus, go with straight walls wherever possible for any that are not directly adjacent to the print plate. Also, keep any walls on your print design as thin as possible … 1 to 3 mm … for the best results. Ensure that there are no mesh errors as these will cause gaps inside the print that obstruct the clarity. Furthermore, orient the object you are printing so that the print direction parallels the longest axis (of the object). Dry the filament for at least 8 hours on the maximum dryer heat setting of 70 deg C for most non-industrial drying units. PETG is extremely hygroscopic and any absorbed moisture will cause bubbles of steam that will cloud the clarity of the print. You can print this filament from the AMS as long as you re-spool it to a plastic spool. Cardboard retains a lot of moisture. Thus, if you put the cardboard spool into your AMS, even with the plastic rims, you’ll end up raising the interior humidity of the AMS. So, how did the print go? Please see the attached video and photos. First, I was amazed at how little stringing occurred at 270 deg C. It did come with over-extrusion artifacts along the seams but that is par for the course for such high nozzle temps. This is why I recommended using the seam profile that creates the least amount of seams, which you can visually confirm in the slicer previews. The bottom wall and layers are amazingly clear. In the attached photos, you can read the text printed on the Overture filament box right through the bottom wall of the print. The side walls of my printed object (a purge chute, waste bin cover) are translucent but more diffuse. If I were to manually polish all the walls of my printed object, I am certain I could achieve “glass like” transparency. So, overall, a good print with excellent results with Overture Transparent PETG on clarity, cleanliness of the print, and its dimensional stability.

Trustpilot

3 weeks ago

1 month ago